Fit testing in the UK is a legal requirement for anyone who is required to wear tight-fitting RPE the first time they use a particular type of respirator, to ensure it fits correctly before it is deployed as a measure of protection.

Developed and manufactured in the USA by OHD, QuantiFit2 is the only device in the fit testing industry which operates using patented controlled negative pressure (CNP) technology.

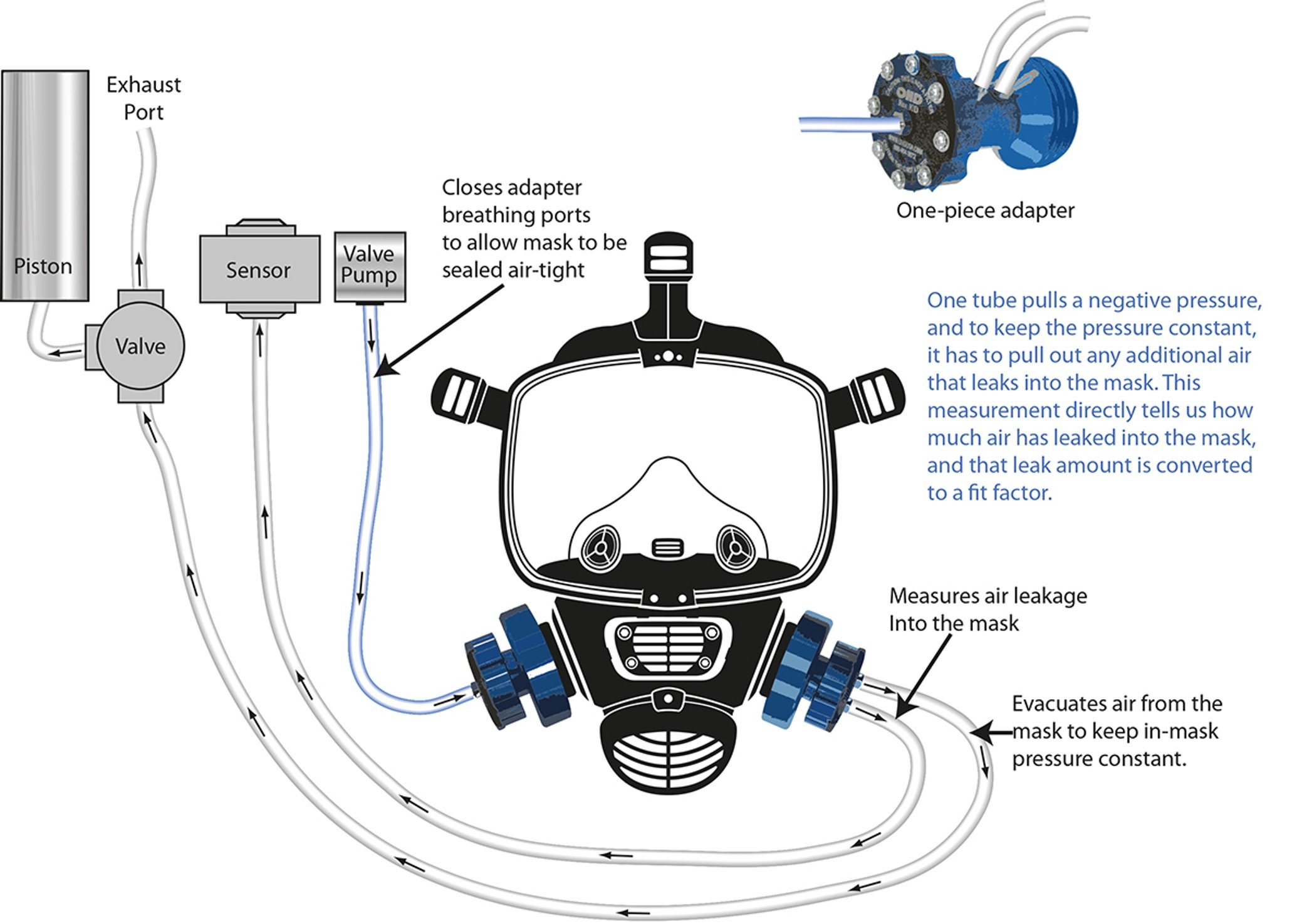

Instead of attempting to compare the particle count inside and outside the mask, this quantitative method directly measures respirator leakage in half- and full-face masks. This method demonstrates that if air can get into the mask, not only particulate but also gases, vapours and fumes potentially can too.

The QuantiFit2 can be used across a wide range of industries and applications including but not limited to aerospace, automotive, chemical, construction & remediation, laboratory & university, environmental monitoring, engineering, food and beverage, oil & gas, pharmaceutical, upstream & offshore and utility companies through to military, emergency services, first responders, the NHS and COVID test facilities.

CNP technology is a fully recognised method of fit testing in the UK and is referenced in the HSE INDG479 ‘Guidance on respiratory protective equipment (RPE) fit testing’ leaflet and in the BSIF Fit2Fit Scheme companion guides.

It works by capping the respirator inlets and propping open the inhalation valves. The test subject holds their breath for no more than 10 seconds after a series of exercises while QuantiFit2 establishes and maintains a controlled negative pressure, or vacuum, inside the respirator. The volume of air drawn out during the test period is directly equal to the leak rate into the respirator.

CNP technology can test in any air, indoors or outdoors, literally anywhere so long as air is present. In comparison, the APC method requires an indoor space smaller than 400 square feet with specific environmental conditions, where the particulate can be controlled and introduced if necessary. There needs to be a large differential between the amount of particulate inside and outside the mask.

However, subjects cannot be tested using APC if they have smoked in the last 30 minutes, as they will exhale particulate which can falsely be interpreted to be seal leakage. Drinking or eating close to an APC test will also throw off the results, so again the test cannot proceed.

CNP fit testing doesn’t have any of these limitations as it’s measuring air, not particles.

The biggest single innovation the new QuantiFit2 offers is the ability to run on battery as well as mains power. This unique development has completely revolutionised the fit testing industry in terms of versatility and removed any previous geographic restrictions.

For the first time ever, fit testing is now truly portable and can be conducted anywhere, with no consumables, not being tethered to a power source or adhering to specific environmental conditions.

Each battery provides more than four hours of continuous testing and can be replaced out in the field. Where mains power is also in use, the battery will be kept fully charged. If accidentally unplugged or during an interruption to the mains power supply, the unit will switch seamlessly from mains to battery power without interruption. A separate charging unit is also available so users can use one battery in the field whilst recharging a second.

In terms of COVID, QuantiFit2 has been developed as an ideal resource for fit testing. Demand has increased dramatically over the last 18 months, especially for reusable respirators due to more individuals being required to wear RPE and the environmental impact of disposable filtering face pieces (FFPs).

Being battery-powered, QuantiFit2 can be used in large uncontained spaces indoors, outdoors or in marquees, offering better ventilation and more COVID-safe conditions, whereas the old APC method requires test subjects to be shut away in a closed room with the fit tester under controlled conditions.

Users can follow on-screen instructions or can be simultaneously tested alongside an unlimited number of other units. This helps to ensure an efficient turnaround speed for group testing.

The new Autostart feature offers touchless testing capability, which helps prevent cross-contamination. Tests can easily be conducted whilst maintaining a safe 2m distance, with clear instructions on the large LCD screen situated on top of the machine to help guide the subject through the fit test.

With QuantiFit2, employers now have the freedom to take the fit test out to their team, wherever they are. Gone are the days of summoning employees to a controlled indoor environment in a centralised location.

Alongside the other benefits of the QuantiFit2, the introduction of the battery option has had a huge impact in terms of minimising disruption and downtime across any organisation undertaking fit testing, especially with the increase in demand the world has witnessed over the last 18 months.

Book a demo today Tel: 01367 899553 solutions@shawcity.co.uk