Shawcity offer free expert and impartial technical support for the lifetime of your instrument or duration of hire.

If you would like technical support, please try to ensure you have your instrument and/or the serial number to hand.

+44(0)1367 899553*

*During office hours:

Monday - Thursday: 8:30am - 5pm

Friday: 8:30am - 4pm

Closed Saturday and Sunday

If you need to view or download the Datasheet or User Manual for your instrument, use the Search Bar on our website to locate your product.

All related documents are found under the images on each product page. If you cannot find the information you require, please contact us via the options above and we will be happy to assist you.

Photo-ionisation Detectors (PIDs) will detect and measure around 400 Volatile Organic Compounds (VOCs). A PID will also detect and measure some inorganic gases.

Today PIDs are used across many industries including petrochemical, manufacturing, marine, pharmaceutical and printing. They are also used by organisations responsible for land clean-up, fire investigation and HAZMAT teams within civilian and the military services.

Over the years PIDs have become more attractive through the reduction of the size and weight of instruments, making them more portable and easier to handle. Portable PIDs have been used for over 40 years and now personal wearable devices are also available to provide individual protection for workers in situations where there is a possibility of over exposure to toxic volatile compounds.

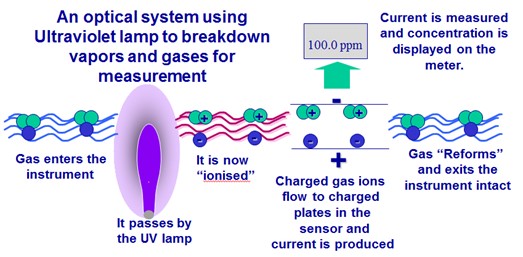

PIDs are very sensitive monitoring devices which allow us to detect hundreds of different compounds at very low levels. A PID uses an ultra-violet lamp to ionise chemicals which are subsequently detected over electrodes, thereby measuring their concentrations in parts-per-million (ppm) or parts-per-billion (ppb).

Straightforward to use with a variety of applications, a PID is best used to detect low levels (0-3000 ppm) of broad band toxic chemicals or VOCs. Breakthroughs in lamp and sensor technology allow a PID to be small, rugged (resistant to contamination and humidity) and affordable.

Main advantages of a PID sensor:

- Instantaneous display, updated every second, for real time monitoring of toxic chemicals and VOCs.

- STEL, TWA and Peak values, updated every minute, accessible to the user at the end of the work shift.

- Threshold monitoring - visual and audio alarms in real time for STEL, TWA and Peak. Alarm signals vary for each condition.

- Data log for compliance and work shift trend analysis.

Gas carrying VOCs enters the PID and passes over the face of the ultra-violet lamp (with a standard output of 10.6eV), which subsequently ionises the VOC sample if it has an ionisation potential less than the output of the lamp.

The charged ions flow to charged plates in the sensor and current is produced. This current is measured and a gas concentration is shown on the display. Only a fraction of the sample is destroyed during this process allowing for sample collection and more detailed laboratory analysis.

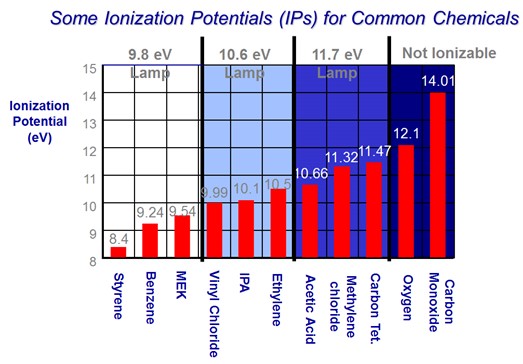

Ionization potential (IP) is typically specified in electron volts (eV) and refers to the energy required to remove a single electron from a single atom or molecule to produce an ion. The IP of an individual element or compound (found in instrument manufacturers’ charts) may be used as an indicator of its detectability using a PID.

A PID lamp generates a specific voltage, the most common being 10.6eV. If the IP of the compound is less than the lamp voltage, then that compound will be ‘seen’ by the PID. Most volatile organic compounds have an IP of less than 10.6 eV, so will be measured.

For those compounds with an IP greater than 10.6eV, a higher voltage 11.7eV lamp is available. This is frequently used to detect and measure compounds that will not be seen by the standard lamp. Any compound with an IP greater than 11.7eV is not detectable by PID.

Unfortunately, the operating costs for this higher voltage lamp are significantly greater, and the lamp lifetime much shorter. This lamp is therefore only used when absolutely necessary.

A lower voltage, 10/9.8eV lamp is also available. This can be used as an alternative to the standard lamp to discriminate between compounds. If two compounds are known to be present and the 10.6eV lamp sees them both it is sometimes possible to substitute the low voltage lamp to only see one of the compounds.

This lower voltage lamp may also be used to effectively ‘screen out’ a large number of compounds that are not of interest. This is used, for example, in Benzene specific instruments widely used in the petrochemical industry.

Anyone involved with chemicals, gases and petrochemical products. Examples of applications include:

A PID will measure the following detectable compounds:

HYDROCARBONS

INORGANICS

There are some compounds with an IP greater than 11.7eV. These compounds cannot be measured using a PID:

There is alternative technology available to measure these substances. If you need further clarification for any compound, contact Shawcity and we will be happy to advise you.

Many PID users will identify VOCs and may not be aware of the compound or compounds that are being measured. If you have no idea regarding the specific compounds, the measurement is still important but further investigation is needed. Without being able to qualify the exact compound, the measurement should be presented as an equivalent reading with reference to the calibration gas used. The calibration gas commonly used is isobutylene, so the gas value is ‘isobutylene equivalent’.

If you know there are several compounds in the sample, it is virtually impossible to accurately identify the health risk. This is an issue if one of the compounds is highly toxic and the others present are mildly toxic. Under these circumstances a PID should be considered a simple screening device, and further consideration given to more detailed analysis.

For further help and advice, please contact us and we will be happy to discuss your specific circumstances.

Most manufacturers recommend calibration of their PIDs with Isobutylene.

Isobutylene is an excellent surrogate calibration gas because the response of most VOCs is reasonably close to, and consistent with, this gas.

The Correction Factor (CF) is the measure of the sensitivity of a PID to a specific gas. The CF will only be used if you have an instrument calibrated with one compound when you are sampling another. The relationship between the calibration gas and the alternative compound determines the sensitivity of the PID to that gas and gives you the Correction Factor.

For example, with an Isobutylene-calibrated instrument, a measurement of toluene will read high. This is because the response of the PID to toluene is different compared to Isobutylene. This difference is the response/ correction factor.

Correction Factor Example:

For toluene the correction factor is 0.5. Therefore, if the instrument reads 100ppm and you know it is toluene, the correct value is 100ppm x 0.5 = 50ppm

Most manufacturers publish a list of response/correction factors for several hundred different compounds. These factors are now usually built in to the PID to allow users to correct the readings.

Example correction factors:

Acetone- 0.7

Ammonia - 8.5

Benzene - 0.5

Butadiene - 0.85

Diesel Fuel - 0.75

Ethanol - 8.7

Gasoline - 1.1

n-Hexane - 3.3

Styrene - 0.45

Toluene - 0.51

Vinyl Chloride - 2.2

Xylene - 0.43

A PID is similar to other continuous, real time gas monitors. It indicates a gas concentration. It also will provide an audible, visual (flashing light) and vibrating alarm when a high concentration is present. PIDs usually have two high alarms to provide an early first warning and a second higher action needed alarm.

Also, 15 minute STEL (short term exposure level) and eight hour TWA (time weighted average) alarms can be provided. The exact capabilities and functions of any particular instrument will vary from model to model.

Because a PID measures numerous different compounds it is important to gather as much information regards the probable gases that are to be measured. Only then can you set the alarm levels with any degree of confidence.

If you know the VOC that is to be measured you can simply configure the STEL and TWA alarm levels in accordance with the HSE’s document, EH40. Because EH40 does not provide instantaneous high alarm limits the setting of these alarms are at the discretion of the user.

Each year our manufacturer approved engineers at Shawcity will inspect and test the performance of your PID. Depending on the model, this service may include:

Lamp cleaning, sensor cleaning, lamp performance test, probe replacement, battery operation time test, display test, external water/dust filter replacement, internal inline pump filter replacement, firmware upgrades, PC communication test, calibration against an NPL traceable source, exterior clean and issue of a service report and calibration certificate.

As well as returning your PID to Shawcity for an annual calibration and service, we recommend you yourself regularly check the performance. Switch on the PID and apply calibration gas. The PID should read between 90-110ppm with a known volume of 100ppm +/- 5%. Depending on the sensitivity you require your instrument to work at it may require calibration.

.

If the weather is cold, instruments stored overnight in vehicles or underheated buildings will take a little longer to warm up. Moisture may condense inside units, giving erratic, unstable or false zero readings.

To avoid problems switch on the instrument and allow it to run for 10-15 minutes before use. Routinely clean the lamp and probe, replace filters regularly and keep your PID on charge when not in use.

Routine cleaning of the PID lamp/sensor will ensure stable readings. It will also help ensure that ‘false positive’ readings are avoided when the gas is present.

It is not possible to give an accurate recommendation as to the frequency, as type and concentration of compound will affect the performance. However, we recommend you change filters monthly or sooner.

If you want to connect extension tubing to a PID only use Teflon tubing. Tygon, rubber and most other types of tubing act like a sponge and absorb most VOCs. Isobutylene, however, is an exception, so you can use Tygon tubing for calibration.

VOC is an acronym for Volatile Organic Compounds. These are carbon-containing molecules that are gaseous at ambient temperatures. They are potentially dangerous to health and the environment and are found in a broad range of industries and locations.

This varies by industry, but derivatives are included below:

Aromatics

BTEX Compounds (Benzene, Toluene Ethylbenzene, and Xylene), most commonly found in petrochemical, oil and gas.

Monitoring should never be mistaken for control. It is a method by which you can establish baseline measures and risk assessments and implement good control techniques; you can then confirm the efficacy of your control using monitoring over a short- or long-term basis. Exposure can be managed on an individual using monitoring if this is deemed to be an adequate part of control measures.

All VOCs have the potential to cause harm in high enough quantities or over long enough periods, but the toxicity of each compound differs greatly. Exposure guidance in the UK is covered by the EH40 guidelines, which is a freely available document discussing Short Term Exposure Limits (STEL- 15 minutes) or over a normalised 8 hour working day Time Weighted Average (TWA).

All mixtures containing VOCs should be supplied with a Material Data Sheet (MSDS) which will specify the quantity of each VOC in the mixture, along with any specific actions that should be taken if exposure occurs.

VOC monitoring can be achieved using different methods, depending on risk and application. Available technologies include but are not limited to PID (Photo-ionisation Detection), FID (Flame Ionisation Detection), Colorimetric Gas Detection Tubes and Gas Chromatography. Selection of the correct instrumentation is very important and is determined by the requirements of your application, so please contact Shawcity for additional advice so we can help you identify the right method.

This depends on the technology. Most PIDs (Photo Ionisation Detectors) are Zone 1 rated but there are lower-cost options which are not. FID (Flame Ionisation Detectors) and Gas Chromatographs are usually Safe Zone use only. In short, always double-check the rating of the instrument before deployment.

This is entirely application driven and dependent on risk. Please contact us to discuss your application in more detail to diagnose the correct measurements you will require.

The ionisation potential of any gas is the amount of energy required to displace an ion and therefore give it a charge which we can detect. All gases in the universe have an ionisation potential, some higher and some lower. In order to detect a gas with a PID (Photo Ionisation Detection) for example, the ionisation potential of the gas must be lower than 11.7eV (Electron Volts) for the gas to be ionised and detected.

We do provide a consultative approach to identifying the correct measurement technology for you and we are able to download and retrieve data for you from an instrument if it has been supplied by us and requested at the outset. Unfortunately, we do not offer the service of interpreting results or making control recommendations. This would be the job of a consultant and we are more than happy to recommend appropriate organisations, such as the BOHS, who will be able to help you further.

Yes. The case is weather resistant. It can tolerate all weather conditions. It should not be placed in direct contact with the ground.

No. The light gray color acts as a thermal insulator. This will prevent an increase of the temperature inside the Enclosure above the ambient temperature. The thermal mass of the Enclosure will also dampen temperature fluctuations normally experienced outdoors.

The Enclosure should be kept a reasonable distance off the ground to prevent any major air flow disturbances caused by the ground from affecting the sample obtained. The manufacturer recommends mounting the Enclosure 3 to 4 feet off the ground.

Relative humidity higher than 80% can cause particle concentration readings to be biased high from the actual concentration of dry particles. The amount that an aerosol's mass concentration increases due to water absorption is a complex function of the particle's material and the atmosphere's absolute humidity (i.e. specific humidity). This humidity effect can bias the DustTrak Aerosol Monitor's readings up to 60% high in the most extreme conditions of high temperature and high relative humidity.

No. The DustTrak Aerosol Monitor has not been tested or certified for operation in a hazardous area where intrinsic safety is required.

Low battery charge is indicated by a battery symbol on the display. The DustTrak Aerosol Monitor will continue to operate for approximately 60 minutes before measurement and logging functions stop. Power will then shut off automatically, but the logged data will be retained by an internal lithium backup battery.

The battery is a 5400 mAH Li-On battery that provides 20 hours of run time. Impactors and cold temperatures will reduce the battery run time.

When the DustTrak Aerosol Monitor is first turned on, it takes about a minute for the instrument to settle down to a stable reading. After warm-up, stable readings can be obtained in 10-15 seconds.

Yes. A major advantage of the DustTrak Aerosol Monitor is its ability to measure volatile aerosols such as water and oil. These cannot be measured accurately gravimetrically because of evaporation from the collection filter.

Yes. The SidePak AM520 Monitor can be used outdoors but it is not considered weatherproof. Therefore it is not suitable for long-term, unattended operation in harsh environmental conditions (i.e. rain, snow, etc.).

Yes. A 95 dB audible alarm sounds and visible red LED lights on the face of the instrument blink when the alarm level is reached.

Five preset alarm levels can be selected from the set up screen on the instrument. Software can be used on a computer to set alarm levels from 0.001 to 999 mg/m3 to be loaded into the instrument.

Fixed systems monitors 24/7 whether personal are in the risk area or not, personal monitors operate only whilst the person takes the monitor in to an area, and until the batteries need replacing/recharging.

Fixed monitors can provide audible and visual indication of an alarm at multiple entries to a room and over a wide area within a room using linked warning beacons, personal monitors can only indicate to people within close vicinity – especially in noisy areas.

Sensors should not be placed near ventilation fans or openings to outside. They should be placed in areas where there is good air circulation, but not in the path of rapidly moving air. Pay particular attention to “dead air spots” where there is little or no air movement.

This depends on the density of the gas relative to air. Heavier than air gases should be detected 6 inches from the floor, lighter than air gas sensors should be placed on or near the ceiling and gases which have a density close to that of air should have sensors installed in the “breathing zone” 4-6 feet from the floor. Consider accessibility for calibration when locating sensors.

Yes. Maintenance on a properly installed, quality system is minimal and need not consist of a visual inspection and verification of operation. Calibration frequency depends on sensor type and application. Typical frequency for commercial applications is one to two times per year. For areas where health hazards may exist, three to four times per year. Industrial applications four to six times per year or even monthly.

Combustible gases form flammable mixtures with air. For each gas there is an explosive range within which the fuel to air mixture will support combustion. LEL is an abbreviation for Lower Explosive Limit, which is the minimum concentration for each gas in air that must be present for combustion or explosion to occur.

% LEL refers to a method of measuring the concentration of a combustible gas where the range of the sensor is set to correspond with the concentration of gas that is below the explosive range. In this case the Lower Explosive Limit equals 100% LEL.

Cross-sensitivity refers to the response of a sensor to a gas other than the target gas (also called an interference gas).

The Gas Data GFM430 can be used for measuring the individual components of biogas (CH4, CO2, H2S and O2) concentration, as well as temperature. A dedicated biogas analyser, the GFM 416 is available to hire or buy.

Ground-gas/landfill monitors are available in both portable and in-borehole versions. For 'spot' surveys there is the portable Gas Data GFM430/5/6 and for long-term borehole monitoring there is the Ion Science GasClam.

The GFM436 portable landfill gas monitor is hand-held and lightweight. Also, monitoring of several boreholes is possible during one site visit.

The Gasclam measures gas (CH4, CO2, VOCs, H2S, CO), concentrations, temperature and borehole and atmospheric pressures.

Measurements can be taken at user-defined intervals. The default setting for the GasClam is to sample every hour and upload data every six hours providing up to two months battery life (with rechargeable D-cell batteries).

After the GasClam has been physically installed in the ground it can start collecting data in less than 2 minutes. The GasClam will continuously collect data at intervals set by the user.

The GFM 436 Landfill Monitor measures six gases: methane, carbon dioxide, oxygen, carbon monoxide, hexane.

We advise that instruments are returned every 12 months so that they can be serviced/ maintained for optimum operational use.

Physiological response to heat stress varies from person to person. Those who may be physically unfit, not acclimatised to the environment or taking medication or drugs may be less tolerant.

An area heat stress monitor measures WBGT (wet bulb globe temperature) in accordance with BS EN 27243. This requires measurement of natural wet bulb, globe and air temperatures.

Yes, the instruments automatically calculates and displays two separate WBGT values for indoor and outdoor applications.

An indication of ‘stay time’ is provided in accordance with several international standards.

The sensor has a reservoir that requires distilled water for accurate readings.

If the wet bulb reservoir dries out inaccurate readings will be provided. Always maintain a reasonable level of water in the reservoir.

The QT44 and 46 models incorporate a 'waterless wet bulb' sensor for calculation of wet bulb temperature. This sensor is ideal when an instrument is required to operate for a long time or is unattended.

This is the time – weighted average of the noise level which an employee is exposed to for a nominal eight hour working day, which is defined by an internal standard ISO. If the daily noise exposure varies from one working day to another, employers may use a weekly noise exposure level to assess the levels of noise to which an employee may be exposed to.

Exposure to high levels of noise, either continuously or as a loud sudden ‘bang’ can have a number of physiological and psychological effects on workers including stress, tinnitus and if exposed to high noise levels over long periods of time, permanent loss of hearing can occur. High noise levels can also interfere with communications in the workplace, leading to an increased risk of accidents.

Our basic noise-indicating instrument is the SD200 (sound detector). The SD200 is a compact, lightweight sound level meter that is ideal for many workplace and community noise measurement surveys. The instrument incorporates an easy to read 'recommended hearing protection level' indicator. Available to hire or buy.

Vibration-induced white finger (VWF) is the most common condition among the operators of hand-held vibrating tools. Vibration can cause changes in tendons, muscles, bones and joints and can affect the nervous system. Collectively, these effects are known as Hand-Arm Vibration Syndrome (HAVS). Exposure to large amounts of whole body vibration (WBV) can cause joint and back pain as well as fatigue, stomach pains and headaches.

Get flexible access to market-leading, innovative equipment without the cost of ownership.

Shawcity offers expert technical and maintenance services for a wide range of instruments.

© Shawcity 2021

Shawcity Limited. Company registered in England No. 1273269 | ISO 9001-2015 certified.

© Shawcity 2021

Shawcity Limited. Company registered in England No. 1273269 | ISO 9001-2015 certified.